General Industral

Other Industrial Use

Purethane® is virtually unaffected by most acids and alkali’s and thus is an ideal long term protective coating for all types of surfaces where corrosion, abrasion, impact, erosion, etc. are present issues. Outside of the typical major applications of our revolutionary 100% solids polyurethane technology, we also assist in strengthening and securing structures in various other use-cases. We have listed some of them below.

Structural Steel

In severe acid or caustic environments Purethane® provides an alternative to continuous recoating of structural steel. One application of Purethane® provides remarkable protection against corrosion from hydrofluoric, nitric, hydrochloric, and chromic acids, salt solutions and caustics. It has been successfully used in the electronics industry on steel I-beams, sludge hoppers and the other similar use-cases.

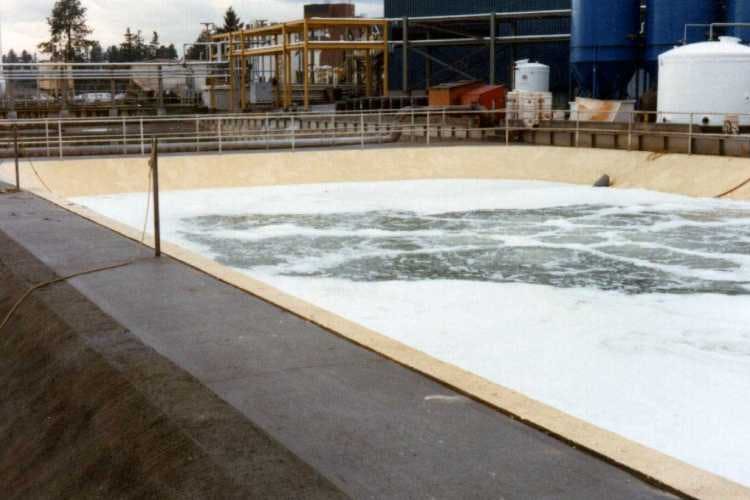

Waste Treatment

Purethane® is an excellent coating for chemical waste treatment ponds, lagoons, tanks pumps, and piping.

Tank Lining

Purethane® is a superior, long lasting interior coating for any type of tank where corrosion is a continuous problem.

Exhaust Systems

Exhaust fans, blowers and ducts are protected against corrosion with Purethane®.

Pump Bases

Pump bases for chemical circulation pumps are subjected to extreme corrosion. A single coating of Purethane® provides lasting protection. Purethane® is also widely used in the pulp and paper industry in Liquor Tanks, Cooking Acid Tanks, Trenches, Effluent Roughs, Ditches, Flumes, Pipelines, Recovery Boiler Area Floors, Structural Steel, Stock Washing Area Floors, Acid Circulation Pumps Bases, caustic Tanks, Bleach Plant and Pump Lining.